The Aerogel Seminar 2018 date is fast approaching. To get a gist of what’s in store, click the video from a previous aerogel conference organized in Hamburg (2014)

Cotton is widely considered as a promising precursor material for aerogels due to its biodegradability, abundance, and non-toxicity. Furthermore, it is a low cost and renewable resource, making it an auspicious material for the addressing of environmental problems. Therefore, numerous studies have reported the utilization of cotton aerogels as superabsorbents for various different applications (e.g. cleaning up of oil spills or water purification).

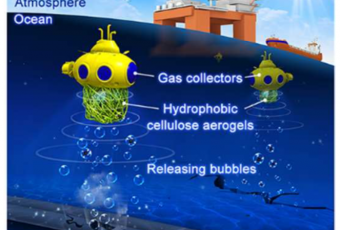

Based on recent developments, allowing for the production of modified hydrophobic cotton aerogels, researchers from the South China University of Technology Guangzhou have come up with a new ingenious field of application — the trapping of methane bubbles, released by underground sea sediments, from water.

This application is of a special interest as methane is a very potent greenhouse gas, being responsible for approximately one fifth of the atmospheric greenhouse effect. Since aquatic system such as lakes, rivers or oceans are considered to be major sources of methane, releasing trapped gases to the atmosphere via bubbles, the capturing and safe storage of methane bubbles originating from marine environments could mitigate the negative impacts of climate change substantially.

In order to explore this idea, the research team from the South China University of Technology synthesized cotton aerogels (CAs) of varying cotton concentrations via freeze-drying. To ensure the hydrophobicity of the aerogels, the CAs were thereafter silanized with methyltrimethoxysilane, using a thermal chemical vapor deposition method. This resulted in stable monolithic cotton aerogels, which showed promising methane absorption characteristics under both static and dynamic conditions.

By submerging the different hydrophobic cotton aerogels (HCAs) in artificial seawater and exposing them to gaseous methane, it was found that the static absorption capacity increased with decreasing cotton concentration (i.e. larger porosity) and increasing submergence depth. Furthermore, the assessment of the dynamic absorptivity of the samples via compression/recovery cycles revealed that the process exhibits an outstanding repeatability, as the samples retained their absorption capacity to large extents.

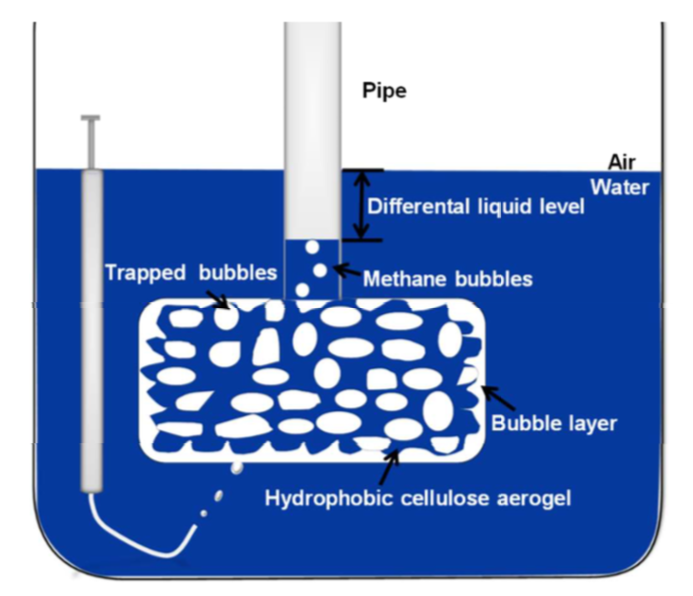

With the aim of investigating a continuous strategy to safely transport methane above sea level, a pipe connecting the HCAs to the water surface was attached to the aerogel monoliths. This approach, which is schematically shown in the figure below, led to a steady and controlled transport of methane to the surface, as the bubbles trapped within the aerogel travelled through the pipe due to the existing pressure difference, resulting in an immediate recovery of the aerogel absorption capacity.

Certainly, the reduction of methane emissions from lakes and oceans could have a substantial positive impact on the world-wide greenhouse gas emissions. Therefore, the novel findings motivate a further investigation of the climate change mitigation potential of the deployment of (aerogel-based) methane bubble absorbents in aquatic systems.

The hydrophobic aerogels investigated in this study are not only captivating because of their excellent methane absorptivity, but also exhibit outstanding properties in terms of bio-compatibility and non-toxicity, paving the way for large scale deployment even in fragile eco-systems.

If further positive results in this field can be achieved, the trapping of methane from seawater could even become an economical process, with the captured methane being sold to compensate for the required investment and operational costs.

More details: Nan Li et al. “A Low-cost, Sustainable and Environmentally Sound Cellulose Absorbent with High Efficiency for Collecting Methane Bubbles from Seawater” ACS Sustainable Chem. Eng. https://pubsdc3.acs.org/doi/pdf/10.1021/acssuschemeng.8b00146

Despite their intriguing characteristics (e.g. ultralow density, high porosity & electrical conductivity), the application of carbon aerogels is generally limited by their poor mechanical strength and brittleness. Researchers from the Zhejiang University (China) were now able to manufacture highly flexible, binary carbon aerogels (bCAs) consisting of graphene and multi-walled carbon nanotubes (MWNTs), which can resist compressive and tensile stresses. These novel bCAs were successfully used as strain sensors to detect complex three dimensional movements.

The novel aerogels were fabricated by creating an aqueous solution equipped of graphene oxide and MWNTs which was then given shape by additive 3D-printing. Thereafter, the structures were freeze-dried before being chemically or thermally reduced.

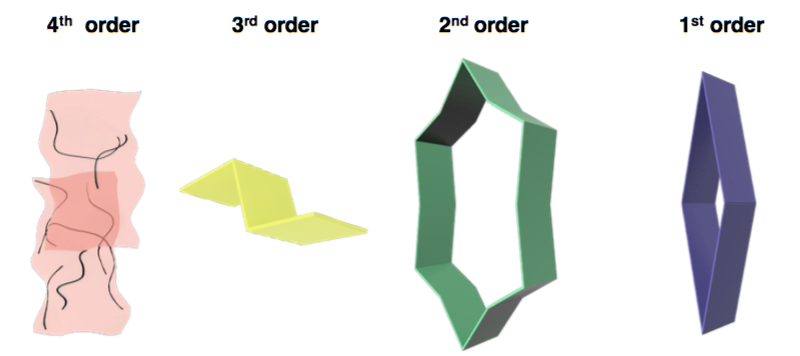

Owing to their hierarchical assembly, which is schematically shown in the figure below, the novel bCAs exhibit an extraordinary stretching stability over a wide range of conditions (e.g. temperatures from 93-773 K). Furthermore, they exhibit a noteworthy fatigue resistance, being able to retain their structural shape to great extents for at least 100 cycles at 200 % tensile strain.

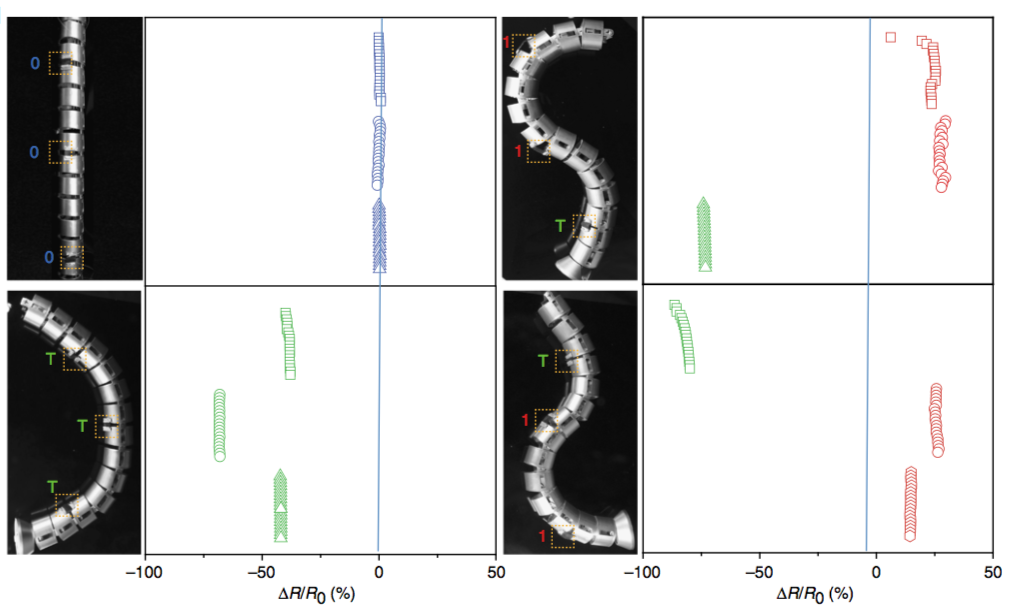

Another key characteristic of the bCAs is their change in resistance in tension (gentle increase) and compression (steep increase). Exploiting this feature, the researchers equipped the joints of a snake-like robot with bCAs to be able to sense the robot’s movements and configurations. As shown in the figure below, a sensor array consisting of three bCAs was sufficient to map the continuously changing configurations and hence accurately identify the robot’s movements.

The authors identify other potential applications of the bCAs in wearable electronic devices, lightweight mechanical devices and fields of application requiring robustness and reliability in the most extreme conditions (e.g. aerospace engineering). Furthermore, the researchers are confident that their assembly method can be deployed for the fabrication of other highly stretchable aerogel materials.

More details: Fan Guo et al. “Highly stretchable carbon aerogels.” Nature Communications. https://www.nature.com/articles/s41467-018-03268-y

Read more: https://phys.org/news/2018-03-rubbery-carbon-aerogels-greatly-applications.html

The German chemical company BASF Polyurethanes GmbH has won the German Design Award for its Excellent Product Design in the category Building and Elements. The jury selected the aerogel insulation material SLENTITE® due to its unique combination of properties, facilitating space-saving insulation concepts which open up entirely new creative possibilities to architects and designers.

The novel aerogel material, consisting of 90 % air, allows for the reduction of insulation thicknesses by 50 %, when compared to standard insulation materials. Besides its outstanding thermal insulation properties, it is the first solid, breathable aerogel panel produced from polyurethane. Furthermore, it is easily machined without excessive dust generation, allowing for tailored shapes & sizes and direct application on walls or facades.

Consequently, the SLENTITE® thermal insulation panels eclipse any commercial insulation material while fulfilling all demands placed on modern building materials.

Its honoring by the German Design Award jury could spark the interest of potential customers and competitors, stimulating the aerogel insulation material market.

Read more:

http://www.german-design-award.com/en/the-winners/gallery/detail/17074-slentite.html

https://www.basf.com/en/company/news-and-media/news-releases/2018/02/p-18-120.html

https://www.bi-medien.de/artikel-24501-bm-extrem-schlanke-daemmplatte-von-basf.bi

The Fifth International Summer School on Aerogels held in Cologne is organized cooperatively by the Hamburg University of Technology (Germany), the University of Salzburg (Austria), the Empa in Dübendorf (Switzerland) and the Department of Aerogels from Institute of Materials Research at the German Aerospace Center. During this workshop participants will be introduced to the fascinating properties of aerogels and perform many lab-on experiments learning how to synthesize and characterize inorganic, organic and bio-polymeric aerogels.

Students, PhD-Students, Postdocs, experienced scientists from universities, research organization and industry are invited to make a unique experience: the manufacturing and characterization of a fascinating nanostructured material.

More information on the Summer School can be found here.