Both economical as well as environmental considerations demand for high-performance building insulation materials to reduce global energy requirements for space heating and cooling. At the same time, devastating events like the Grenfell Tower fire, which broke out in 2017 in West London causing 72 deaths, highlight that besides low thermal conductivities, insulation materials must be fire retardant and robust even under extreme conditions.

Targeting this, researchers from the University of Science and Technology of China Hefei have now successfully manufactured a composite aerogel material which excels in both these categories. The novel phenol-formaldehyde-resin (PFR)/SiO2 aerogel which is composed of a three-dimensional, interpenetrating binary network structure, exhibits lower heat conductivities than conventional insulation materials and possesses outstanding fire retardant properties as well as great structural stability when being subjected to high temperature flames.

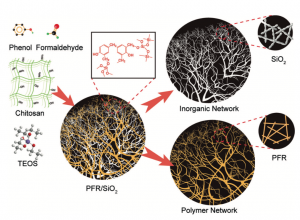

Synthesis of the gel matrix consisting of an inorganic SiO2 network and a polymeric PFR network (see Figure on the right) was achieved via the so called chitosan templated method. First, the precursors TEOS, acetic acid, and phenol were solubilized in an ethanol water mixture, which was then added to an aqueous chitosan solution, before adding formaldehyde. Thereafter, the resulting mixture was hydrothermally treated at 160 °C for 10 hours resulting in the hydrogel samples. Lastly, the hydrogels were solvent exchanged with acetone before being supercritically dried with CO2, resulting in the final composite aerogel.

To assess the impact of SiO2 contents on the final aerogel properties, samples of different SiO2/PFR ratios were produced. Characterization of the different aerogels showed that densities increase with increasing SiO2 content, but remain below 75 g/cm3 even for 80 % SiO2 (PSi-80). Additionally, both the strength and the elastic modules were found to increase with SiO2 content, while all aerogel samples could be compressed by more then 60 % without significant structural collapse occurring.

In terms of the samples’ thermal stability aerogels of high inorganic contents exhibited superior properties during cone calorimetry evaluation (lower thermal degradation and lower heat release rate), highlighting the positive impact of SiO2.

For the PSi-70 sample, exhibiting a great mechanical and thermal stability, a minimum thermal conductivity of 24 W/Km was obtained at low temperature and low relative humidity (T=-12 °C, RH<10 %). Remarkably, decent thermal conductivities (<45 W/Km) were also obtained at increased temperatures and high relative humidities (T=22 °C, RH>75 %), greatly outperforming commercial insulation materials such as EPS or mineral wool.

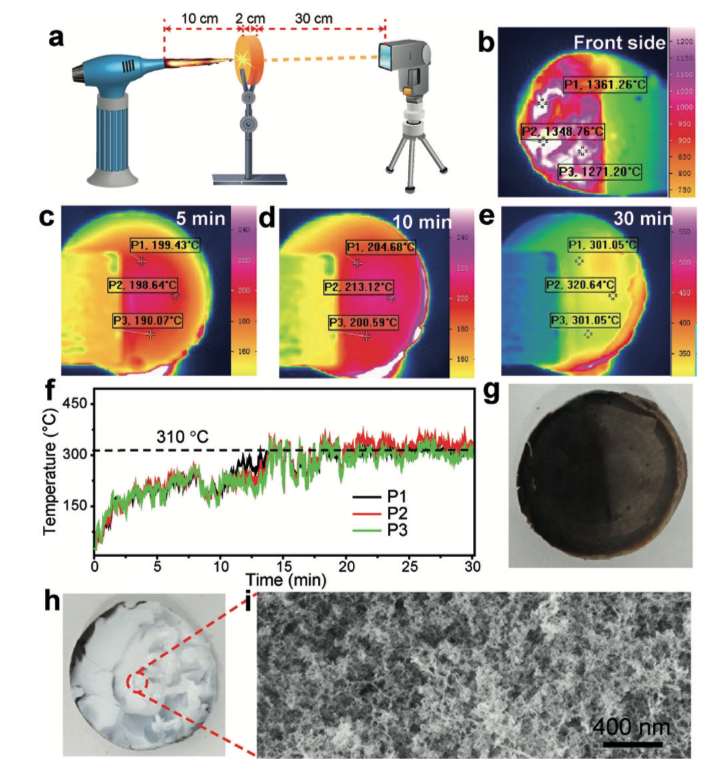

To test the aerogels’ flame resistance, slabs of the composite aerogel were subjected to a propane/butane flame (see Figure below, a), which generates a flame temperature of approx. 1300 °C. Astonishingly, the PSi aerogel retained its monolithic structure even after 30 minutes of flame exposure (see Figure below, g and h). Moreover, while only the white SiO2 network was left on the directly exposed front side, the sample maintained its structural features on the backside to great extents. This was attributed to the fact that the low thermal conductivity of the aerogel prevented a stark increase in temperature on the backside (see Figure below, c-e), despite the large temperatures (>1300 °C) on the sample frontside. As the backside temperature was below 310 °C even after 30 minutes of flame exposure (see Figure below, f), the authors concluded that the employment of the composite aerogel insulation guarantees the prevention of the collapse of reinforced concrete structures, which is reported to occur above 350 °C. Similar flame resistance testing of commercial PF foam and a PFR/attapulgite composite aerogel resulted in larger backside temperatures (>400 °C) and sample disintegration, underlining the outstanding characteristics of the investigated PSi aerogels.

In summary, the authors conclude that their novel aerogel is a promising candidate for next-generation insulation materials, as it unites great mechanical stability and fire retardant properties with outstanding characteristics in terms of thermal insulation. While certain challenges regarding economic scalability and rentability are still to be overcome, phenolic-silica aerogels surely seem very auspicious from a technical perspective alone.

More details: Zhi-Long Yu et al. “Fire-Retardant and Thermally Insulating Phenolic-Silica Aerogels” Angew. Chem. Int. Ed. 2018, 57, 4538 –4542, https://onlinelibrary.wiley.com/doi/abs/10.1002/anie.201711717

Read more at: https://www.advancedsciencenews.com/fire-retardant-binary-network-aerogel/