Researchers from the Kyoto University (Japan) successfully synthesized transparent, machinable, scalable, super-compressible, highly elastic and super-insulating polyvinylpolymethylsiloxane aerogels and xerogels. Remarkably, the study reports that these outstanding features were present not only in aerogels produced using supercritical drying, but in those produced using ambient pressure drying, too.

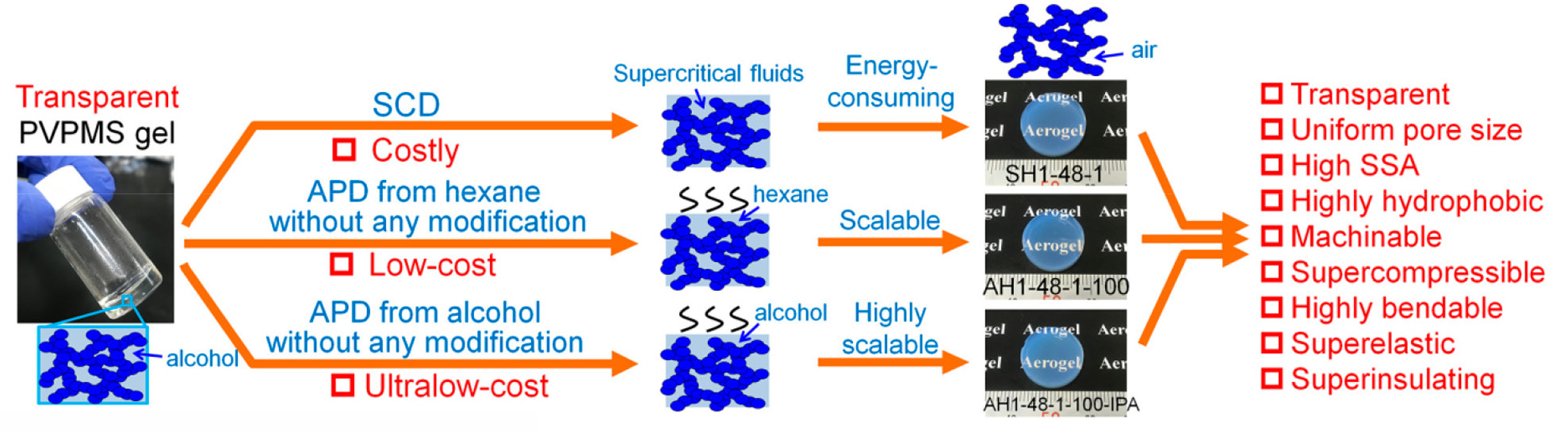

The sample preparation was achieved by mixing vinylmethyldimethoxysilane (VMDMS) or vinylmethyldiethoxysilane (VMDES) with 1-5 % of di-tert-butyl peroxide (DTBP), to initiate the radical polymerization at 120 °C, yielding a transparent viscous liquid mainly containing polyvinylmethyldimethoxysilane (PVMDMS) or polyvinylmethyldiethoxysilane (PVMDES). Thereafter, BzOH, H2O and tetramethylammonium hydroxide (TMAOH) were added to the liquid and the mixture was heated to 80 °C for one hour to obtain transparent and flexible gels. Prior to solvent exchange with isopropanol (IPA), the gels were aged between four or five days at 80-100 °C. Removal of the liquid was subsequently accomplished in three different ways (see Figure below): (1) supercritical drying with CO2; (2) solvent exchange into n-hexane followed by drying at ambient pressure; (3) direct drying from IPA at ambient pressure.

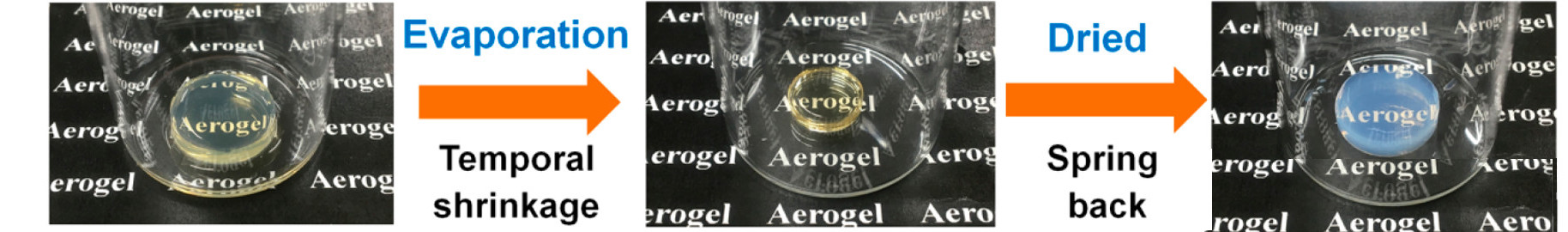

It was established that key to the intriguing properties of the dried aerogels and xerogels are their homogeneous porous nanostructure, composed of flexible hydrocarbon chains chemically cross-linked with polymethylsiloxanes. Notably, this type of nanostructure structure exhibited low densities (0.16-0.22 g/cm3) and heat conductivities (15.0-15.4 mW/m K), as well as high specific surface areas (900-1000 m2/g), good transparency (>80 % light transmittance), and extraordinary flexibility (see attached video). Additionally, the flexible network structures allowed for a recovery of the evaporation-induced gel shrinkage through a “spring-back” effect (see Figure below), making the supercritical drying step dispensable.

In summary, these findings imply that an ultra-low cost pathway to manufacture aerogels by ambient pressure drying while still preserving extraordinary properties required for applications as superinsulators has been established. This means that one of the main obstacles for the broad application of aerogels — their high manufacturing costs — has been overcome, which might pave the way for their large scale deployment.

More details: Zu et al.; Transparent, Superflexible Doubly Cross-Linked Polyvinylpolymethylsiloxane Aerogel Superinsulators via Ambient Pressure Drying , ACS Nano, January 8, 2018. https://doi.org/10.1021/acsnano.7b07117

Video of aerogel bending test: Click Here