With both global oil consumption and environmental awareness steadily increasing, both economical as well as environmental aspects require an efficient, reliable, and cheap method to remove spilled oil from water. Selective oil absorption is an auspicious technique for this purpose since it is low cost, generally achieves high absorption capacities and offers the opportunity to recycle the working material. Yet, commercial absorption materials still suffer from several shortcomings (e.g. poor oil water selectivity, complicated fabricating process), which is why further advances in material engineering are required in order to obtain applicable oil absorbents.

With the aim of finding an efficient, environmental compatible and economical sorbent material, researchers from the Dalian Polytechnic University (China) have now successfully synthesized a low-cost, organic aerogel based on corn straw and filter paper, which exhibits good performance as an oil sorbent from aqueous media.

The outstanding feature of the synthesized aerogel material is that it originates from corn straw, which is generally considered as a waste product and thus nowadays is still being burned, positively contributing to global greenhouse gas emissions. However, its abundance, low-cost and biodegradability make it an potent raw material for large scale applications. Its main disadvantage — the inherent brittleness of materials originating from it — was overcome by the addition of filter paper pieces to the precursor material leading to the required flexibility of the final aerogel material.

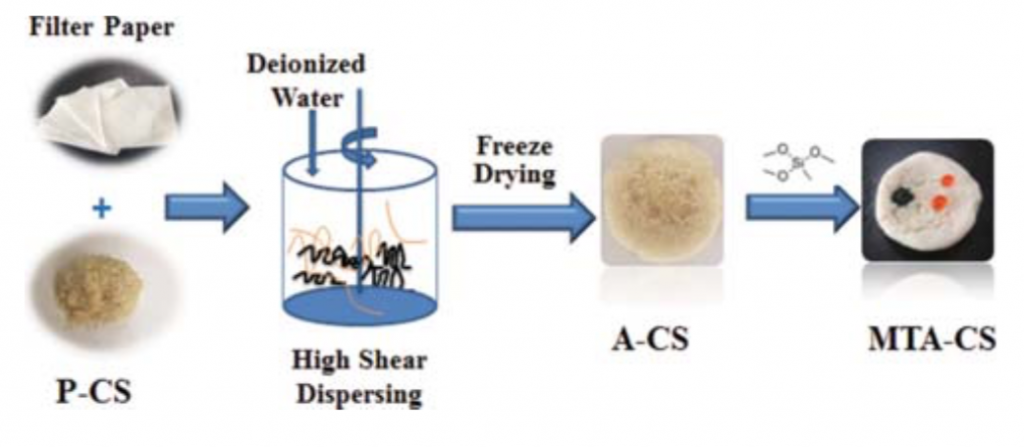

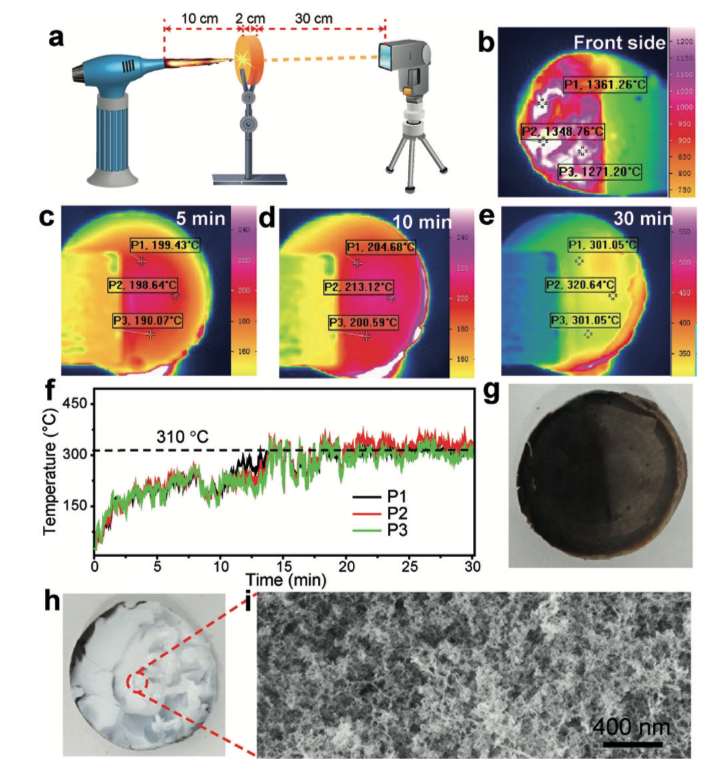

For the preparation of the aerogels, the corn straw was first ground then washed with sodium hydroxide before hydrochloric acid was added. Subsequent filtration and drying led to corn straw particles (P-CS), which were then dispersed in water together with small pieces of commercial filter paper via vigorous stirring. Thereafter, the dispersion was frozen at -25 °C for 12 hours before freeze drying at -55 °C for 36 hours. The final step of the production process, which is shown in the figure below, was the hydrophobization of the corn straw aerogel (A-CS) through chemical vapor deposition of methyltrimethoxysilane (MTMS).

Analysis of the final freeze-dried aerogel structures unveiled that the material exhibited a porous 3D-structure and a good thermal stability up to 250 °C. Dependent on the solids content and the P-CS:filter paper ratio densities ranging from 14 to 58 mg/cm3 were attained, while porosities between 96 and 99 % were achieved. Water contact angle measurements showed a successful hydrophobization, with measured contact angles reaching values up to 152°.

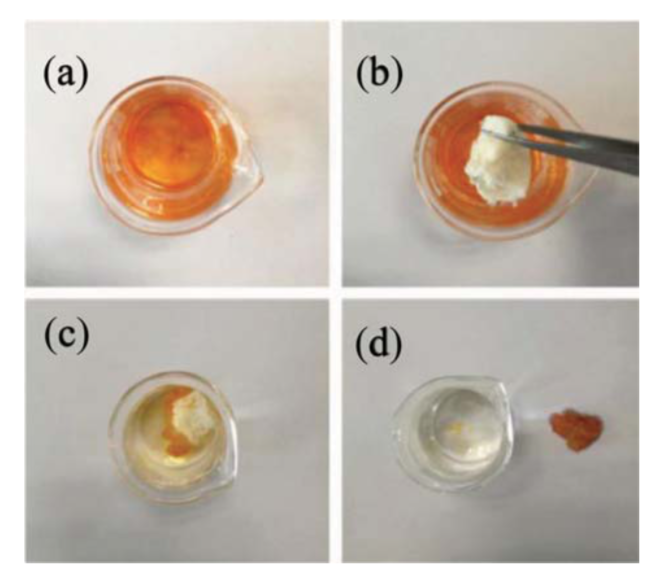

Investigation of the selectivity and absorptivity for a range of different solvents showed that while water absorptivities were below 1 g/g for the hydrophobized corn straw aerogels (MTA-CS), absoprtivities of organic solvents such as oil or DMF were in the range of 40 g/g. Hence selectivities towards organic solvents were extremely high. Moreover, the MTA-CS did not only absorb the organic phase with a high selectivity, but also in a rapid fashion, leading to fast oil removal from aqueous solutions (see figure below).

With the novel low cost absorbent material synthesized by the Chinese research team disadvantages of conventional oil absorption were overcome, which might pave the way for the widespread utilization of biodegradable oil sorbents originating from corn straw. Certainly, it will be interesting to see whether novel bio-based oil absorbing materials can outperform their synthetic counterparts (e.g. poly(melamine- formaldehyde), polyurethane and polystyren) in the future.

More details: Yuan Li et al. “Preparation of corn straw based spongy aerogel for spillage oil capture” Korean Journal of Chemical Engineering May 2018, Volume 35, Issue 5, pp 1119–1127, https://link.springer.com/article/10.1007/s11814-018-0010-3

Read more at: http://www.chemengonline.com/inexpensive-renewable-aerogel-shows-promise-handling-oil-spills/?printmode=1