Due to their outstanding mechanical properties, such as high flexibility and rigidity, graphene aerogels are considered a promising type of aerogel for multiple applications. Recent studies found that by accurately tailoring the three-dimensional alignment of the graphene sheets inside the aerogel, these properties can be further enhanced. Simulations even predicted graphene structures exhibiting only 4.6 % the density of steel but 10 times its strength. Therefore, the ordered alignment of graphene sheets has has become a crucial part in graphene aerogel synthesis.

Because of its cheapness, scalability and environmental compatibility, freeze casting has been shown to be an efficient way to achieve the desired alignment of graphene-oxide (GO) sheets in a frozen monolith. This is the case, since GO sheets are rejected from the ice crystal upon freezing, which means that by determining the freezing direction, the alignment of the resulting GO scaffold can be tailored, as the sheets are “trapped” in between the resulting ice crystals. Through deploying various different directional freezing techniques, multiple GO-alignments (e.g. micro-honeycomb or ordered lamellar structures) have already been achieved.

Motivated by these findings, researchers from the Institute for Basic Science and the National Institute of Science and Technology in Ulsan (Korea) have managed to synthesize vertically and radially align graphene aerogels, resembling the structure of a micro-turbine.

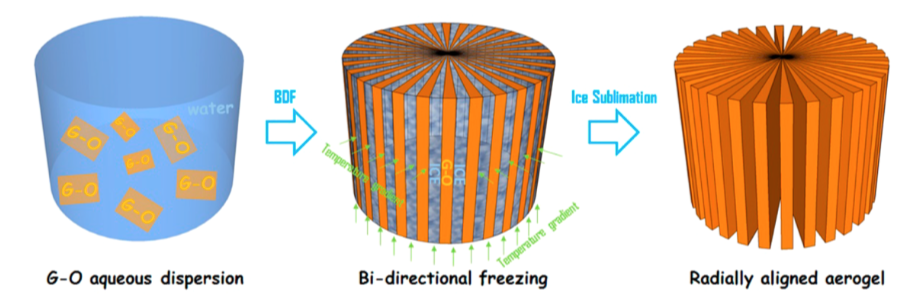

The stated aerogels were manufactured by freeze casting an aqueous GO dispersion in a tailor-made setup in which two perpendicular temperature gradients (one in radial and one in axial direction) could be generated. With this setup, the researchers aimed at a simultaneous axial and radial alignment of the GO-sheets inside the frozen dispersion, resulting in a turbine-like GO scaffold, as shown in the figure below.

Initial tests conducted in this bi-directional freezing (BDF) setup unveiled that interactions between water and the GO sheets (e.g. H-bonding) influenced the ice crystal growth, thereby entailing undesired final crystal shapes and sizes, which is why several additives (e.g. ethanol, cellulose and chitosan) were successfully employed to reduce these unwanted interactions.

Following the freeze-casting procedure in the presence of these additives, the resulting monoliths were freeze-dried and reduced chemically using hydrazine vapor, yielding dry and reduced graphene aerogel structures.

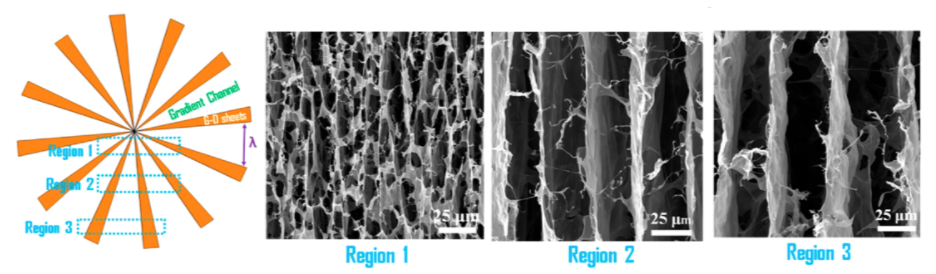

The characterization of the obtained graphene aerogel monoliths showed that a highly ordered structure with the desired features (e.g. increasing lamellae channel widths towards the outer edges of the monolith) were obtained, which can be seen in the figure below. Furthermore, the aerogels exhibited a density of 6.9 g/cm3 and a specific surface area of 45.9 m2/g.

To highlight the superiority of the novel ordered structure, the mechanical properties and absorptivities of the BDF aerogel were compared to those of aerogels of an unordered and a honeycomb pore structure. Apart from its outstanding rigidity, being able to carry ∼10 000 times its own weight without deformation, the “turbine” aerogel exhibited neither a substantial loss in strength nor visible plastic deformation upon multiple successive compression cycles. Even after 1000 compression cycles at 50 % strain, the BDF aerogels exhibited a deformation as little as 8 %, while the unordered and honeycomb structures exhibited similar or larger values after just 15 cycles. This was attributed to the fact that the blades of the turbine-like structure did not brake or dislocate when being strained.

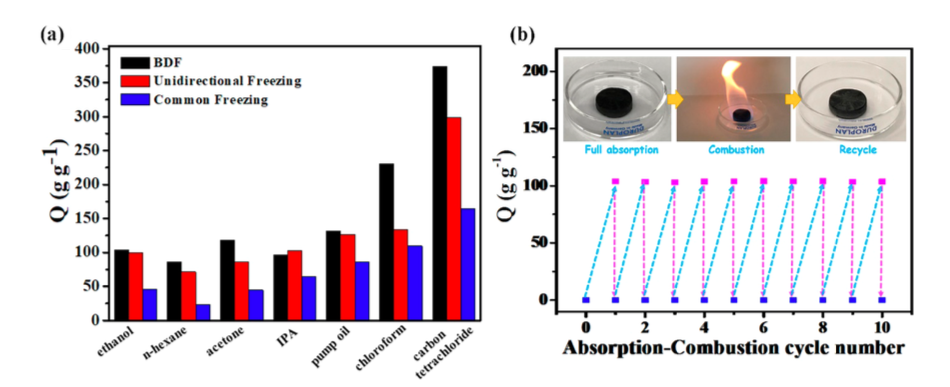

To assess the absorptivity of the different samples, the maximum uptake of different liquid organic compounds (e.g. ethanol, IPA, acetone, pump oil, etc.) from an aqueous solution was investigated. Not only did the BDF aerogel outdo its counterparts in terms of the absorption capacity, but it also exhibited an extraordinary cycling stability when repeatedly removing the solvent from the aerogel pores via combustion subsequent to absorption (see figure below).

These outstanding findings once more highlight the unique features graphene aerogels offer and reveal that enhancements in their characteristic properties are readily attainable. Hence, further substantial advancements in the field of graphene aerogels are only a matter of time, making these materials one of the more auspicious candidates for future groundbreaking innovations. Certainly, the aerogel community will be captivated by this remarkable material for many years to come.

More details: Wang et al. “Freeze-Casting Produces a Graphene Oxide Aerogel with a Radial and Centrosymmetric Structure” ACS Nano, March 2018. https://doi.org/10.1021/acsnano.8b01747