Coal fired power plants will play a substantial role in energy production for the majority of industrialized nations until at least the middle of this century. This is an issue since the large-scale combustion of carbon-based resources is a major contributor to the rising atmospheric CO2 levels. In order to achieve the ambitious multilateral goals to lessen the detrimental effects of global warming by stabilizing the global CO2 levels outlined in the Paris Agreement, the greenhouse gas emissions from coal fired power plants will need to be reduced drastically.

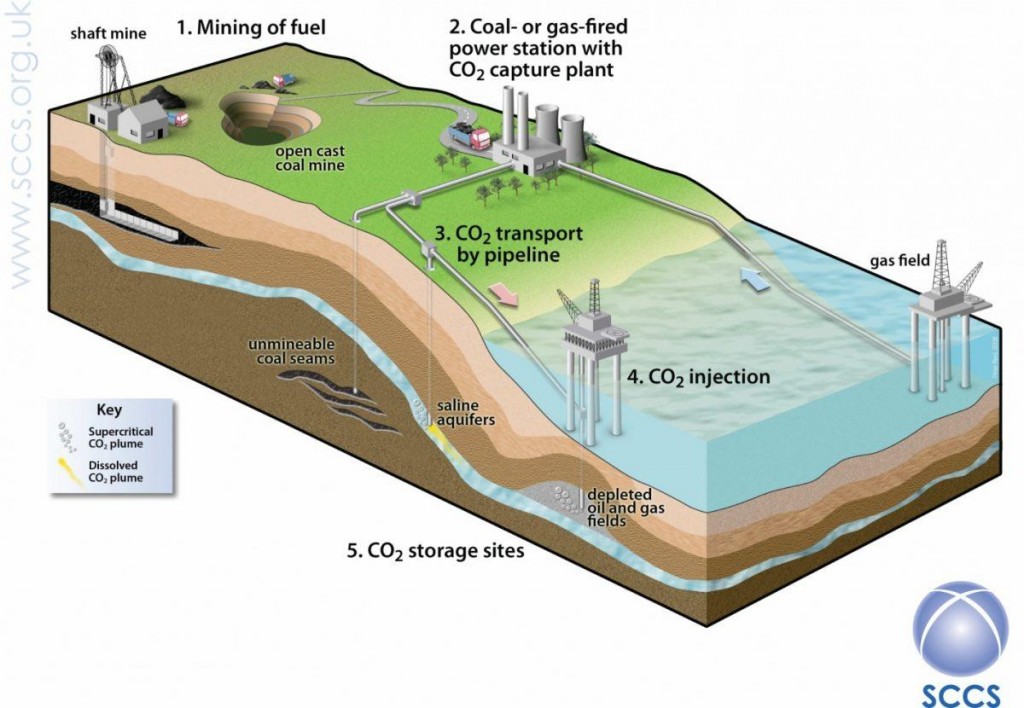

One way to achieve this reduction in emitted greenhouse gases without abandoning coal-based power production is the capturing and sequestration of emitted CO2 (see graphic below). This can be done by retro-fitting existing power plants with carbon capture and storage (CCS) units, which remove carbon dioxide from flue gas, before storing it in a designated location. Most commonly, temperature-swing adsorption (TSA) processes, utilizing aqueous amine solutions as sorbents, are proposed for CO2 capturing. However, the regeneration of the amine solution results in an energy penalty which drastically reduces the thermal efficiency of the power plant. Therefore, alternative sorbents requiring less energy for regeneration are under investigation.

In a joint effort, a project team consisting of Aspen Aerogels, the University of Akron, ADA-ES, and Longtail Consulting have synthesized and tested solid amine functionalized aerogels (AFA) in a bench scale fluidized bed reactor, in order to assess their potential for future application in CCS.

It was found that the AFAs synthesized by Aspen Aerogels showed promising CO2 adsorption behavior and good stability over numerous adsorption-desorption cycles. On top of that, the novel solid sorbents possess significantly lower heats of reaction with CO2 than commonly deployed liquid and solid sorbents. In a subsequent step, the AFAs were coated at the University of Akron, yielding pellets possessing a good cyclic stability in the presence of SO2. The novel AFA pellets were then tested in a bench scale fluidized bed reactor to determine their physical properties (e.g. fluidizing gas velocities, void fraction, etc.) in such a reactor setup.

Based on those findings, Longtail Consulting modeled the hydrodynamic and heat transfer properties of the solid aerogel sorbent in the fluidized bed reactor and finalized the process requirements. Subsequently, a techno-economic analysis (TEA) of the entire CO2 capturing unit (assuming 90 % capturing efficiency) fitted to a coal fired, supercritical steam cycle power plant producing 550 MWe was performed. Despite offering a promising behavior from a technological perspective, the TEA revealed that utilizing novel AFA sorbents results in approx. 20 % higher levelized electricity costs. This finding was mainly attributed to the fact that the attrition of the material during fluidization was unknown, yielding high variable costs for the selected scenario. Additionally, a relatively high apparent particle density inside the fluidized be reactor led to a massive pressure drop, causing a surge in auxiliary electricity input.

In light of these findings, the project team concluded that further testing under practical conditions and simultaneous optimization of the AFAs will be essential to make solid sorbents an economical alternative to state-of-the-art aqueous amines.

As the need for creative solutions to reduce greenhouse gas emissions is only increasing, it is promising to see that the vast potential of aerogels is being explored to address climate change. Whether or not solid sorbents can be successfully utilized in TSA in an economically reasonable way may prove to be one of the key factors determining the success of CCS.

Full Report: https://doi.org/10.2172/1349123

Read more at: https://www.osti.gov/scitech/biblio/1349123