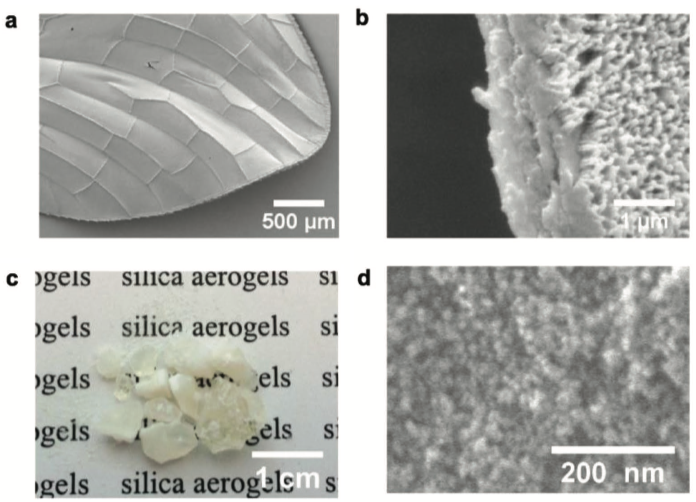

In search for a straight-forward and economical drying technique for aerogel materials, removing the main obstacle for the wide-spread application of aerogel materials — their tremendous costs — researchers from the University of Newcastle have been inspired by the way dragonflies and damselflies dry their lightweight and porous wings under ambient conditions.

In the course of their research the scientist stumbled upon the fact, that dragonflies dry their highly porous wings — which make up only 2 % of their entire bodyweight despite their large size — in a matter of a handful of hours (sometimes even as little as one hour) during their final metamorphosis into the adult. They hypothesized that this rapid but at the same time gentle drying process of the aerogel-like wings at ambient conditions can be attributed to the involvement of just one simple chemical compound — bicarbonate.

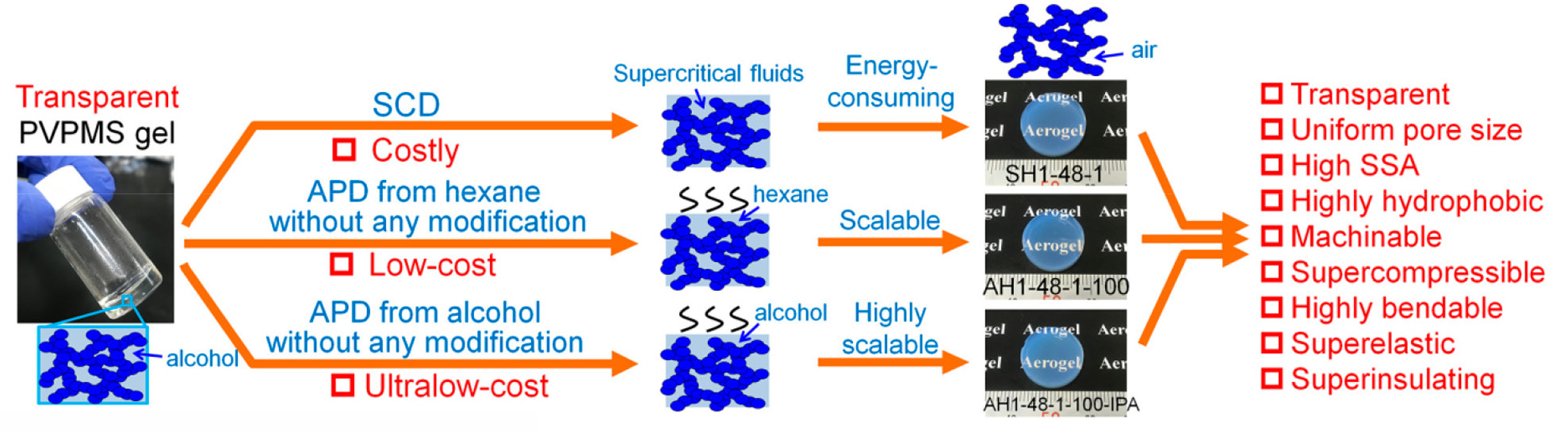

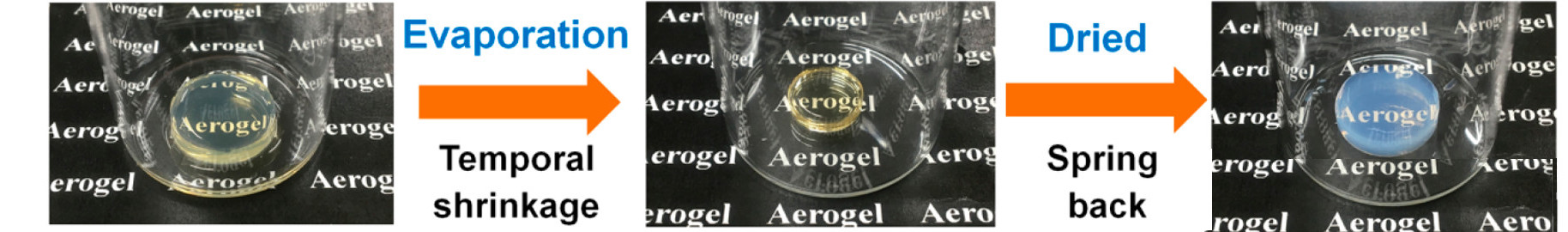

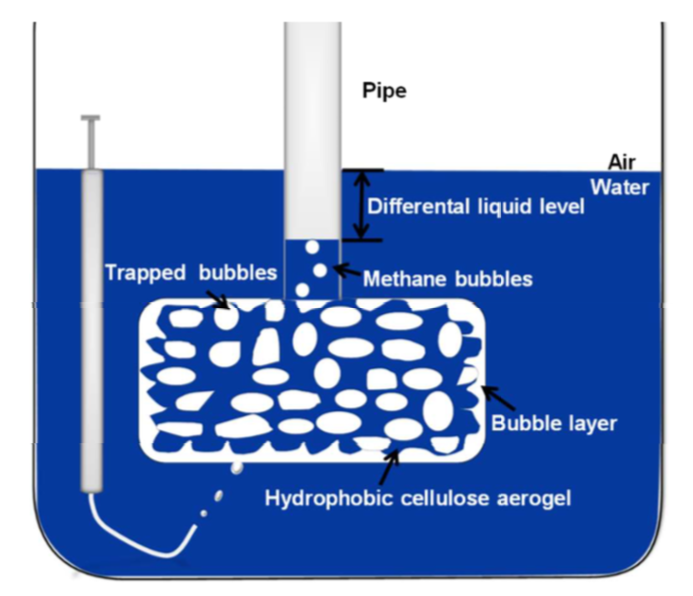

The formation of sodium chloride (NaCl) and CO2 from sodium bicarbonate, which takes place upon the addition of trimethylchlorosilane (TMCS), was found to be a straight forward technique to produce CO2 inside an aqueous porous medium, with the formed gas preventing pore collapse in the course of successive ambient pressure drying (APD), mimicking this process (supposedly) occurring in nature. As schematically shown in the figure on the right, this means that CO2 formed in situ works as a stabilizer

Schematic of novel APD drying technique deploying sodium bicarbonate and TMCS. of the gel pores, acting against the capillary pressure arising when the solvent is removed from the gel network via APD.

The suggested drying technique was tested using silica gels synthesized from tetraethoxysilane, which were placed into a sodium bicarbonate solution for 24 h after aging. Before drying the gels at ambient pressure (60 °C), small quantities of TMCS were poured upon them to initiate the CO2-forming reaction and hence prevent pore collapse. To further enhance the aerogel properties by removing the by-product NaCl from the gel pores an additional washing step was added to the procedure either after or during the drying step.

The resulting aerogels were found to exhibit similar properties as samples prepared via supercritical CO2 drying, exhibiting bulk densities as low as 0.06 g/cm3, porosities exceeding 98 % and specific surface areas of up to 700 m2/g, highlighting the great suitability of this drying technique for the manufacturing of silica aerogels. Further testing showed that the same process can also be applied to dawsonite (NaAlCO3(OH)2) aerogels synthesized with aluminum sec-butoxide and therefore is not limited to silica aerogels.

Certainly, the most outstanding characteristics of the suggested aerogel synthesis route are its simplicity, cost-efficiency, scalability and wide applicability, making it a strong alternative to conventional drying techniques. Especially its ultra low material cost, estimated at $4 per kilogram of aerogel, and the absence of any specialized or hazardous processing conditions (such as elevated temperatures or pressures and toxic materials) could propel the presented approach to market maturity and hence make aerogel materials accessible for commercial sectors, such as the building or clothing industry.

More details: Han et al. “Bioinspired Synthesis of Monolithic and Layered Aerogels” Advances Materials. https://doi.org/10.1002/adma.201706294

Read more at:

http://www.millenniumpost.in/world/dragonfly-wings-inspire-new-generation-of-aerogels-296492 https://phys.org/news/2018-04-world-oldest-insect-aerogels.html

The Association of Advanced Porous Materials (Advapor) is to offer a € 3000 award to the “best” PhD completed in the field of Advanced Porous Materials. Defense must occur before June 2019.

The Association of Advanced Porous Materials (Advapor) is to offer a € 3000 award to the “best” PhD completed in the field of Advanced Porous Materials. Defense must occur before June 2019.

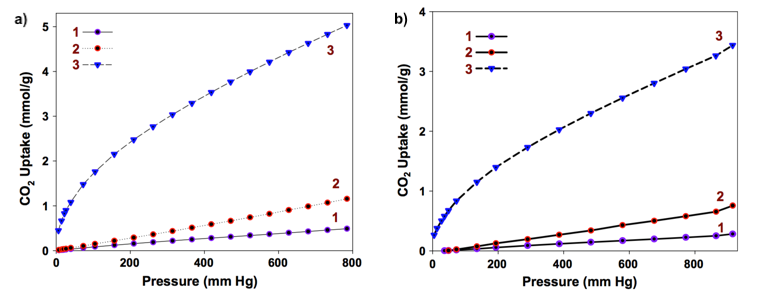

CO2 adsorption isotherms at 1 atm and 0 °C (a) and 1 atm and 25 °C (b) for chitin aerogels (1), carbonized chitin aerogels (2) and KOH-activated chitin aerogels

CO2 adsorption isotherms at 1 atm and 0 °C (a) and 1 atm and 25 °C (b) for chitin aerogels (1), carbonized chitin aerogels (2) and KOH-activated chitin aerogels