New Ultralight Multiwalled Carbon Nanotube Aerogels

Researchers lead by Dr. Lei Zhai at the University of Central Florida have fabricated a multiwalled carbon nanotube (MWNT) aerogel with an astonishing density of just four milligrams per cubic centimeter!

The work was recently published in ACS Nano and you can view the full manuscript here.

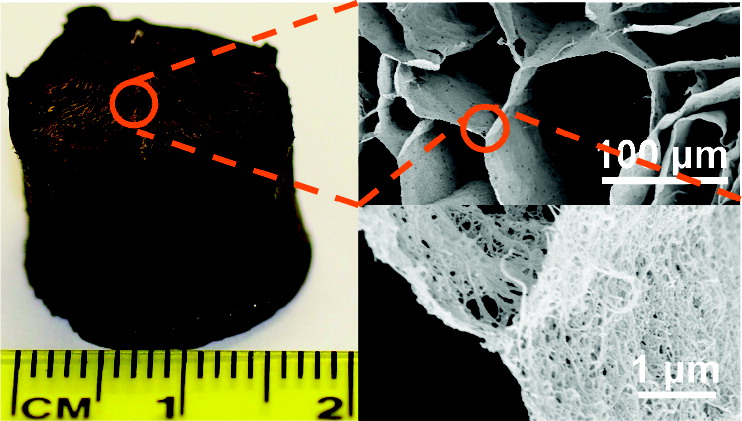

This material is particularly interesting because it is composed of a dispersion of MWNTs which leave a honeycomb structure with controllable porosity. More-so, the aerogel has a large surface area and conducts electricity very well, but is a thermal insulator. This is an ideal characteristic for electronics.

Notably this is not the first aerogel made from carbon nanotubes (or CNTs for short if you’re hip to the materials crowd), nor is it the first CNT-based aerogel to exhibit amazing elastic properties. But it’s a new pathway to making CNT-based aerogels and the resulting materials are pretty cool.

Hype alert: There is a statement being circulated on the Internet that one of the MWNT aerogels these researchers made is the lowest-density aerogel (and thus solid) ever produced. Unfortunately, this is not the case: scientists at Lawrence Livermore National Laboratory have previously produced a silica aerogel with a density of only 1.1 mg/cc, these ones here are 4 mg/cc.

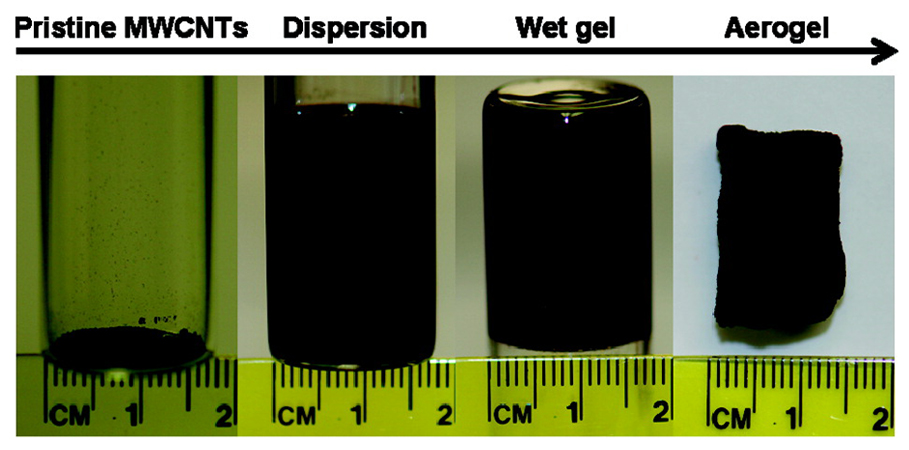

So how are they made? Here’s the gist. Pristine MWNTs are dispersed as individual tubes in chloroform with a compound called poly(3-hexylthiophene)-b-PTMSPMA (P3HT-b-PTMSPMA) by sonicating for 13 min. This anchors a molecule called PTMSPMA on the surface of the nanotubes. The dispersion of MWNTs then gels in several minutes to several hours depending on the concentration of MWNTs. The resulting gel is aged for 12 h at room temperature and then solvent exchanged into methanol to remove chloroform. An aqueous ammonia solution is then added to crosslink the gel for 12 h by hydrolysis and condensation of the PTMSPMA, during which time the gel shrinks a bit. Finally methanol and ammonia are removed by exchanging the gel into water and the gel is freeze-dried to obtain MWNT aerogels. Note the use of freeze drying here instead of supercritical drying is possible thanks to the improved mechanical properties of the gels which make them more resistant to cracking during solvent removal.

The MWNT aerogels are impressively strong in compression and extremely elastic (squishable) exhibiting a rapid rebound. According to the paper, these properties, along with a high degree of porosity make the material a promising candidate for chemical and pressure sensing.

httpv://www.youtube.com/watch?v=jH8jOVSv-Mg