Nickel Oxide Aerogels

Materials

- Nickel(II) chloride hexahydrate, NiCl2•6H2O

- Propylene oxide

- Absolute (200-proof) ethanol

Optional

- Nickel(II) nitrate hexahydrate, Ni(NO3)2•6H2O

Warning!

Propylene oxide is a known carcinogen (exposure can cause cancer), and epichlorohydrin is probably too. If you plan on doing this procedure, take the proper precautions to prevent your exposure to the vapors of these substances by using a fume hood in a lab, if possible, or at the very least a fitted respirator (gas mask) with the right organics cartridges and a well-ventilated space, on top of the usual splash goggles, gloves, long pants, and closed-toe shoes.

Look under Explore > Information About Chemicals to see where you can find health and safety information about these and other chemicals.

If you can’t use these substances safely, don’t use them until you can!

Gel Preparation

- Weigh out 0.37g of NiCl2•6H2O (1.56mmol).

- Dissolve NiCl2•6H2O in 2.5mL of 200-proof ethanol. You will get a clear light green solution.

- Add 1.0g of propylene oxide (17mmol) to the solution.

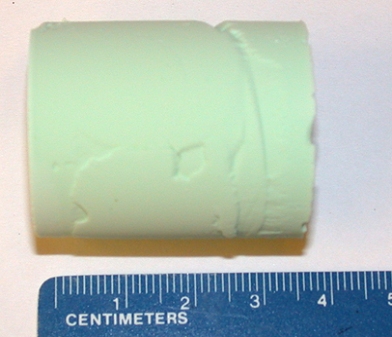

- A rigid, light-green opaque gel will form. Gel time is 30 min.

What Doesn’t Work

- Using 0.47g (1.6mmol) of Ni(NO3)2•6H2O instead. This gives a green precipitate within 60 min after addition of the propylene oxide.

- Using water for the solvent. No gelation will occur.

Gel Processing Conditions

- Cover the gels and age for at least 24 h under ambient conditions.

- Exchange into 200-proof ethanol at least four times over the course of several days to a week.

- Place gels in supercritical dryer. Exchange into liquid CO2 over the course of 2–3 days.

- Supercritically dry. A suggested procedure would be to heat the CO2 through its critical point (31.1°C and 72.9 bars) to ~45°C while maintaining a pressure of ~100 bars. Depressurize at a rate of ~7 bar h-1.

What You Should Get

A light green, monolithic nickel(II) oxide aerogel with approximately the following properties:

- Density 0.098 g cm-3

- Surface area 413 m2 g-1

- Pore volume 1.15 cm3 g-1

- Average pore diameter 11.3 nm

References

-

Alexander E. Gash *, Joe H. Satcher Jr., Randall L. Simpson, “Monolithic nickel(II)-based aerogels using an organic epoxide: the importance of the counterion”, Journal of Non-Crystalline Solids, 2004, 350, 145–151. DOI: 10.1016/j.jnoncrysol.2004.06.030

I love the color!