Organic Aerogels

Materials

- Resorcinol, 1,3-dihydroxybenzene (a white solid)

- Formaldehyde solution, 37 wt% in water (may contain a stabilizer such as methanol)

- Sodium carbonate, Na2CO3

- Distilled or deionized water

- A stirring plate with a magnetic stirrer

- An oven that can maintain 80°C

- Some air-tight sealable mold, for example, a glass test tube with a rubber stopper, or a polypropylene bottle or vial and accompanying screw-on top

- It’s best if the opening of the mold is as wide as the body of the mold so you can actually get your gels out

- The mold should not melt or plastically deform at 80ºC

- Plastic molds that you can cut apart with a razor blade make it easy to get gels out

Gel Preparation

- To start off, we’re going to prepare a dilute catalyst solution. To do this, weigh out 0.20 g of Na2CO3 and dissolve it in 100 g of water. Put this catalyst solution aside.

- Weigh out 1.00 g of resorcinol.

- Dissolve resorcinol in 47.1 g water (this is a new beaker, not the catalyst solution you just prepared). This will take some thorough stirring. Resorcinol will fake you out and make you think it’s not dissolving but it does all dissolve eventually. It’s okay if you have little chunklets left over that just don’t seem to stir away.

- Add 1.47 g of formaldehyde solution.

- Measure out 2.41 g of catalyst solution and add this to the mixture.

- Seal the mold and stir the solution for 24 h (make sure to put your stir bar in first before sealing the mold).

- After 24 h, transfer the mold into an oven at 80°C. The gel will set within a few hours to a day, but leave it in there for 3 days or so.

Variables You Can Play With

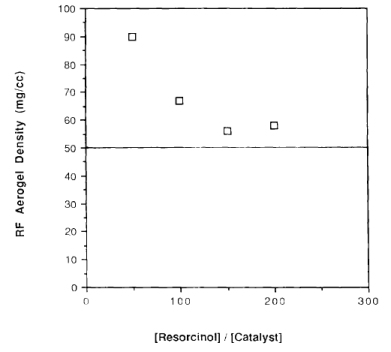

The resorcinol to catalyst ratio can be adjusted to change the gel time (more catalyst means faster gel time), which will also end up affecting the density of the gel as well.

As always you can adjust the amount of solvent (in this case water) to adjust the density of the resulting gel. This formulation should give an aerogel with a density of ~0.20 g cm-3.

- Try 96.5 g of water instead to achieve a target density of 0.10 g cm-3

- Try 195 g of water instead to achieve a target density of 0.05 g cm-3

- Note if you try to dilute the solution lower than a target density of 0.05 cm-3 you will still get lower density aerogels but they might be a little denser than you expected by 20-50%

- Try using 4.81 g catalyst solution and 44.7 g water to speed up gelation, but note this will increase the aerogel density

- Try using 9.63 g catalyst solution and 39.8 g water to further push gel time and even further increase aerogel density

Gel Processing Conditions

- Remove your gel from its mold and solvent exchange into acetone (preferred), methanol, or isopropanol over the course of 3-5 days, exchanging the solvent at least once a day.

- Place gels in supercritical dryer. Exchange into liquid CO2 over the course of 2-3 days.

- Supercritically dry. A suggested procedure would be to heat the CO2 through its critical point (31.1°C and 72.9 bars) to ~45°C while maintaining a pressure of ~100 bars. Depressurize at a rate of ~7 bar h-1.

What You Should Get

The gel should be dark, cranberry-sauce red in color with a consistency similar to cranberry sauce from a can or gelatin dessert (like Jell-O® jigglers). If the gel is orange you can still make an aerogel with it but note it hasn’t fully crosslinked and so it probably won’t be as strong.

The aerogel you will get should be similarly colored and transparent, and squishy like green floral potting foam as opposed to friable like a silica aerogel.

If you used a higher density variation, the gel may be very dark, almost black.

The surface area of the aerogel will depend on the resorcinol to catalyst ratio. For a target dilution of 0.05 g cm-3

- An RC ratio of 200 should yield ~575 m2 g-1

- An RC ratio of 150 should yield ~700 m2 g-1

- An RC ratio of 100 should yield ~760 m2 g-1

- An RC ratio of 50 should yield ~900 m2 g-1

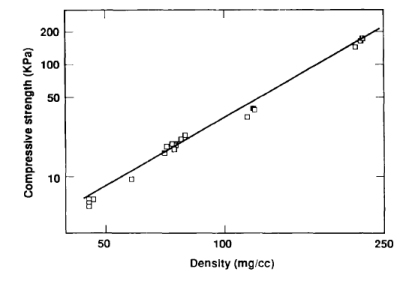

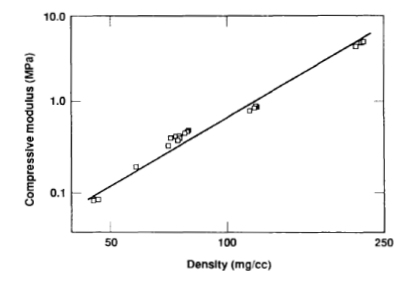

The compressive strength of the aerogels can be tailored from 5 to 200 kPa just by adjusting the density. A 0.2 g cm-3 RF aerogel is about five times stronger than a 0.1 g cm-3 RF aerogel, and about 20 times stronger than a 0.05 g cm-3 RF aerogel! Also, doubling the density makes the aerogel about 10 times stiffer.

Wait! There’s More!

RF aerogels are suitable precursors for making carbon aerogels, which conduct electricity! Check out the pyrolysis procedure.

References

-

Richard W. Pekala and Fung-Ming Kong, “A Synthetic Route to Organic Aerogels–Mechanism, Structure, and Properties”, Lawrence Livermore National Laboratory online report, No. 208379, 1988, retrieved from http://library.llnl.gov/uhtbin/cgisirsi/0/0/0/60/55/X.

hi, i ride bikes and am interested in this technology, in theory, could it be used to create a ultralight, ultra strong bike frame? im 17 and v ery interested if you could email me i would be very grateful, thanks zack

zack.666@hotmail.co.uk

Can aerogel be preared at home?

I am a 17 year old boy of india who needs it for a science project.

And this is the best topic I have got!

Hi Jignesh,

Absolutely! I myself made aerogels at home when I was your age!

Please look at the Make section and read through the articles there. The downside is that you’ll need to find all of the correct parts, which can be a little pricey, but for a few hundred dollars you can make it work!