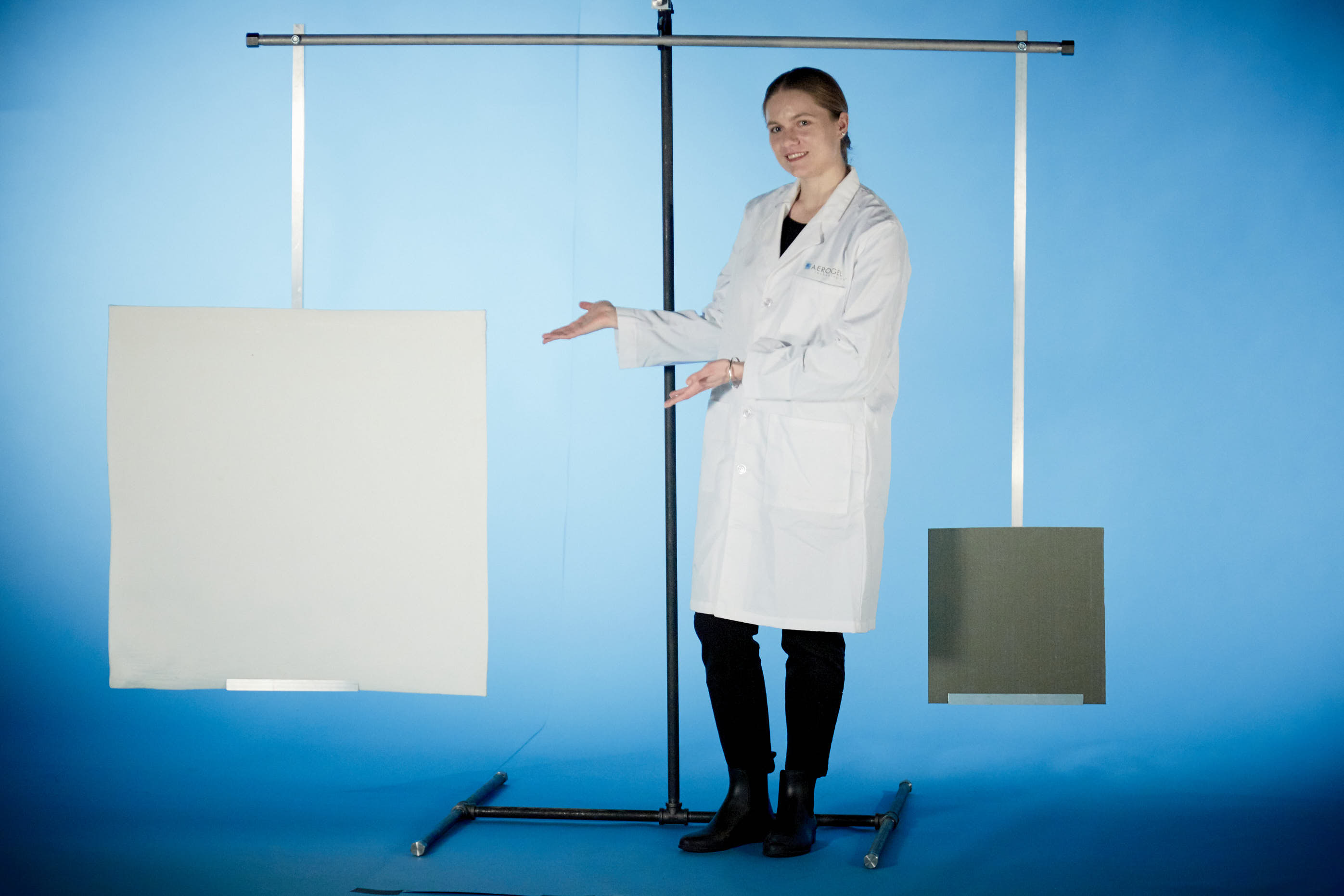

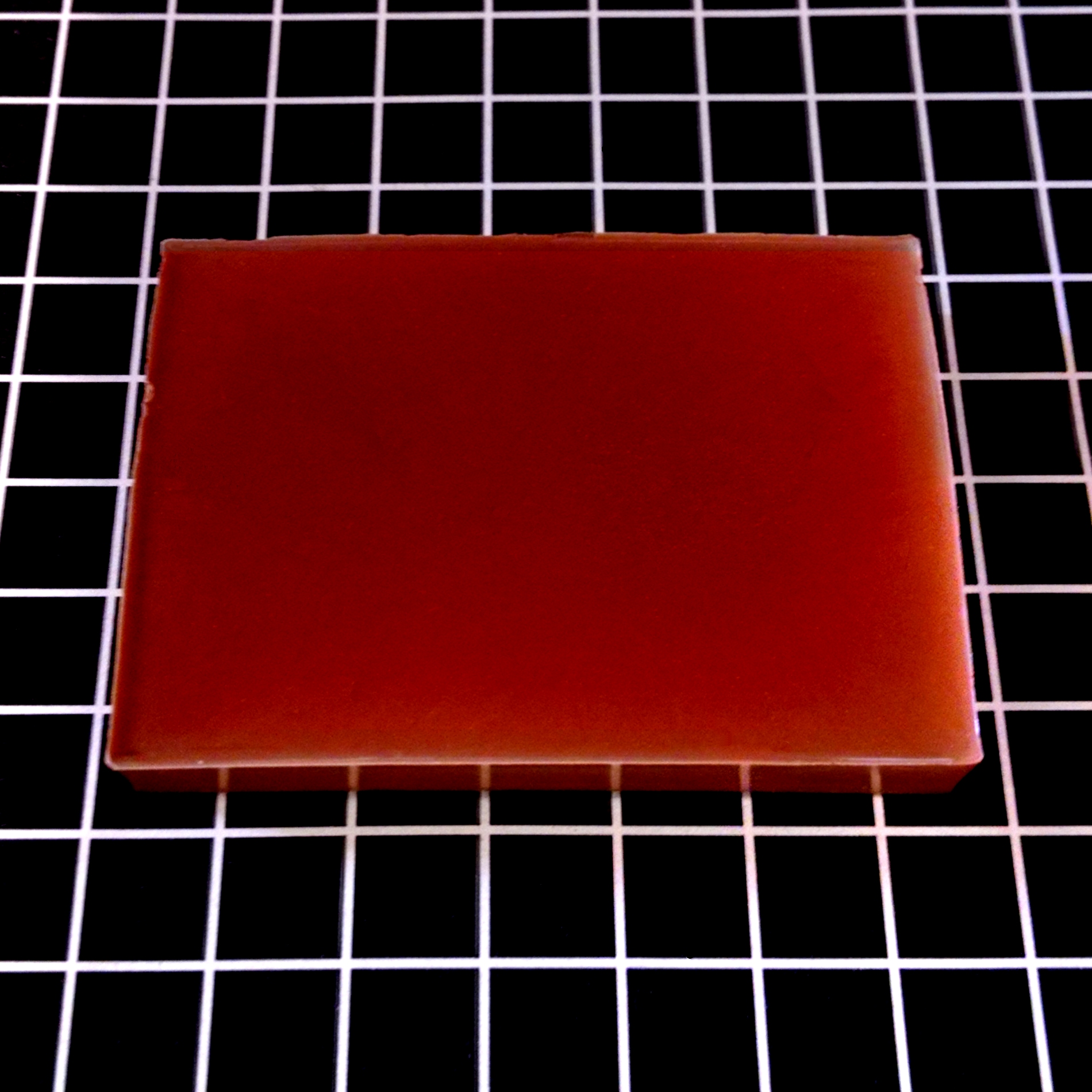

Cabot Aerogel has just released a new dust-free high-temperature superinsulating aerogel blanket called Aeroclad™. For those of you who are unfamiliar with aerogel blankets, they are generally made by combining silica aerogel (which is brittle but superinsulating) with fibers (which are flexible) to make a composite that has the superinsulating advantages of silica aerogel but unlike native silica aerogels, can be flexed, rolled, cut, and sewn. Previously, there were only two types of blanket materials in town—Aspen Aerogels’ blankets (Spaceloft, Cryogel, and Pyrogel), made by casting a silica aerogel coating onto fibrous inorganic (for example, fiberglass) battings, and Cabot Aerogel’s blanket (Thermal Wrap), made by fusing polymer fibers and aerogel particles together in a “bird’s nest” setup. Aspen’s materials have the advantages of high-temperature stability, but tend to kick up dust when handled aggressively (which while completely safe, causes trouble for some applications). Cabot’s Thermal Wrap, on the other hand, is essentially dust-free, but has the minor side effect of melting above 180°C (350°F). Not so good for those blowtorch experiments.

Cabot’s new Aeroclad blanket, however, combines the best of both worlds—by fusing aerogel particles and inorganic fibers together into a composite, Aeroclad is dust-free and high-temperature stable. According to Cabot, Aeroclad is two times better insulating that current insulation products used in industry, including fiberglass, mineral wool, and calcium silicate.

A major application for the new Aeroclad blanket will be in refineries, where shockingly less than 20% of all pipes are insulated. For an industry where energy = $, that’s a pretty good indication that insulating pipes must really suck if they don’t do it more than they do. And it does suck. Current insulating materials trap moisture underneath, causing the pipe to slowly corrode over time—a dastardly, expensive problem called corrosion under insulation, or CUI. Fortunately, Aeroclad is also hydrophobic, meaning it repels water and protects pipes from corroding.

“The Cabot Aeroclad blanket delivers the unparalleled performance and benefits of an aerogel product while addressing a clear market need for dust free and superior corrosion performance,” says Cabot’s Matthew Greenfield, commercial manager, Energy and Industrial, Cabot Aerogel. “Cabot has built a reputation in the industry for its unmatched customer service both in the field and in insulation product design to address specific application needs. We are actively working with several partners to commercialize this product to meet the evolving requirements and demands of the global industry.”

Cool stuff Cabot! Or should we say hot stuff? (Running out of heat-related puns…)

Stephen Steiner | January 10th, 2013 |

1 Comment »